SheetCAM TNG has carved out a specific niche in the CAM market by focusing on what matters most: precision and ease of use for CNC plasma, laser, and waterjet cutting. It does not try to be a jack-of-all-trades 3D modeling tool. Instead, it excels at the 2D and 2.5D tasks that drive workshop productivity. Professionals choose this software because it handles the messy parts of CAD drawings—like gaps or overlapping lines—much better than most high-end alternatives.

Version 6.0.28 brings refinement to an already stable platform. In a workshop environment, downtime is expensive. This update focuses on better pathing logic and improved compatibility with modern DXF exports from various design suites. Fabricators rely on this software to bridge the gap between a raw design and the final G-code without forcing the user through a steep learning curve. It is a tool built for people who need to get parts off the machine quickly.

Choosing the right CAM software is often the difference between a clean cut and a wasted sheet of metal. SheetCAM TNG 6.0.28 maintains its reputation for being lightweight yet powerful. It provides the granular control needed for complex lead-ins and nesting while remaining accessible enough for small shops. If you are tired of fighting with overly complex software just to cut a flat plate, this version offers the stability and directness required for professional results.

Key Features

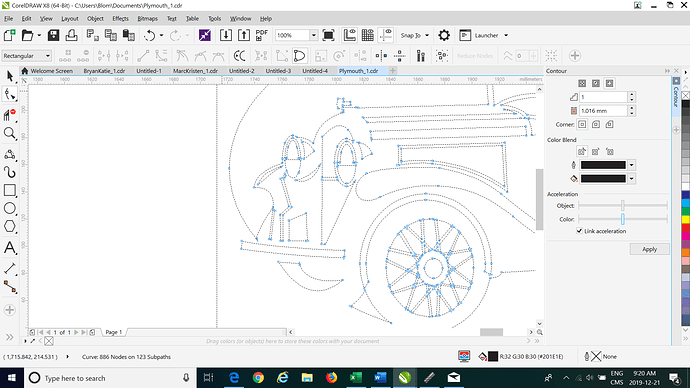

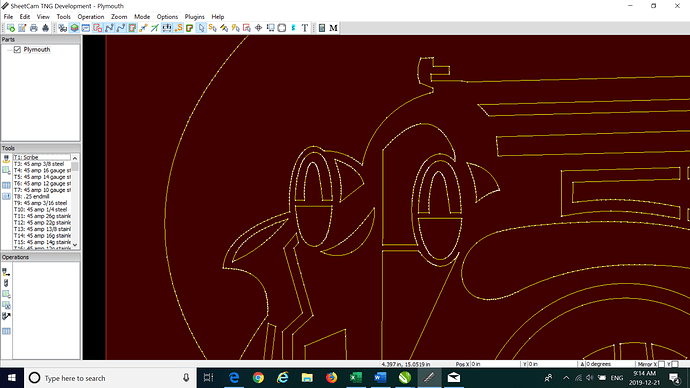

User-Friendly Interface

SheetCAM TNG features a simple and intuitive interface, making it easy for both new and experienced users to navigate and start using the software quickly.Precise Toolpath Generation

The software helps generate accurate toolpaths based on your design. It supports plasma, laser, waterjet, and CNC milling machines, ensuring the toolpath is optimized for your specific type of machine.Customizable Post Processors

SheetCAM TNG offers the ability to customize post-processors, ensuring that the G-code it generates is compatible with a wide range of CNC machines. This flexibility helps integrate the software into your existing setup.Multiple Cutting Machine Support

SheetCAM TNG can handle various cutting machines, from plasma cutters to CNC routers. This makes it ideal for shops with different types of CNC equipment.Material and Job Setup

The software allows you to easily specify material types and thicknesses, ensuring that machine settings are adjusted correctly for each project.Simulation and Verification

With SheetCAM TNG, you can simulate the cutting process before running it on a machine. This allows you to catch potential errors early, saving time and material costs.Automatic Nesting

One of the standout features is automatic nesting, which optimizes the layout of parts on a material. This reduces material waste and helps improve cost efficiency.

Screen Shots

You Can Also Download:

System Requirements

- Also Operating System: Windows 2K/Vista/7/8/8.1/10

- Memory (RAM): 1 GB of RAM is required.

- Hard Disk Space: 20 MB of free space required.

- Processor: Intel Pentium 4 or later.

SheetCAM TNG 6.0.28 Free Full Activated

Download – 24 MB / v4.0.0 | File Pass: 123